3D Printing Revolution: Understanding the Technology and Its Applications

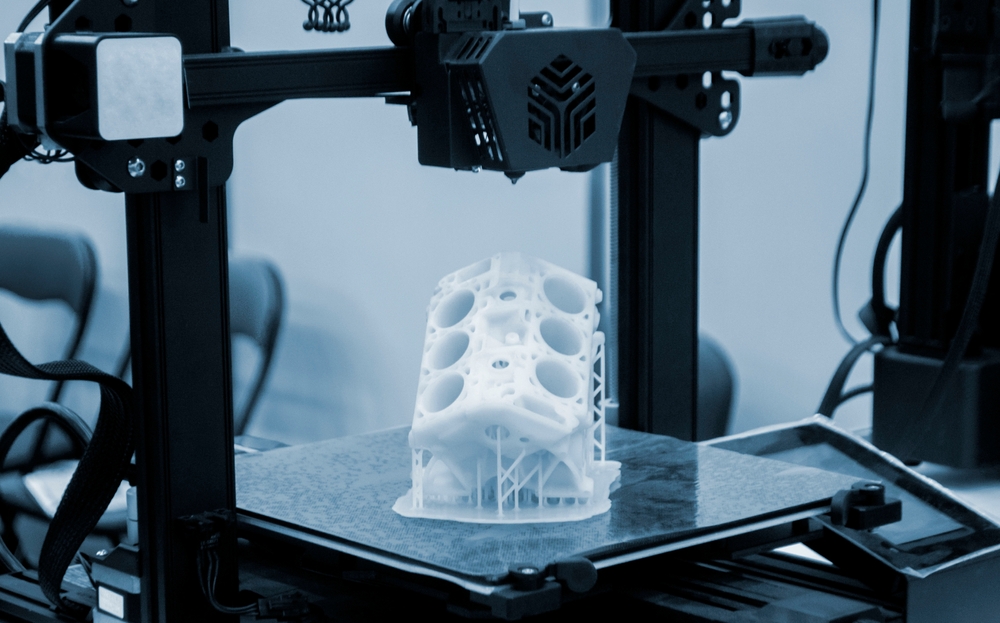

3D printing, also known as additive manufacturing, has revolutionized the way we create objects. This technology allows for the production of three-dimensional objects from digital designs, layer by layer. From rapid prototyping to custom manufacturing, 3D printing has found applications across various industries, transforming traditional production methods and opening up new possibilities for innovation.

What is 3D printing and how does it work?

3D printing is a process that creates physical objects from digital 3D models. It works by depositing materials, such as plastics, metals, or ceramics, in layers to build up the desired shape. The process begins with a 3D design created using computer-aided design (CAD) software. This design is then sliced into thin layers by specialized software, which the 3D printer uses as a blueprint to construct the object.

The most common 3D printing method is Fused Deposition Modeling (FDM), where a thermoplastic filament is heated and extruded through a nozzle to create each layer. Other methods include Stereolithography (SLA), which uses light-sensitive resin, and Selective Laser Sintering (SLS), which fuses powdered materials with a laser.

What are the main types of 3D printers available?

There are several types of 3D printers, each suited for different applications and materials:

-

FDM Printers: These are the most common and affordable 3D printers, ideal for hobbyists and small businesses. They use thermoplastic filaments and are great for creating prototypes and simple parts.

-

SLA Printers: These use a laser to cure liquid resin, producing high-resolution objects with smooth surfaces. They’re often used in jewelry making and dental applications.

-

SLS Printers: These printers use lasers to sinter powdered materials, typically nylon or metal. They’re used in industrial settings for creating complex, durable parts.

-

Metal 3D Printers: These specialized machines can print with various metal powders, creating strong, functional parts for industries like aerospace and automotive.

-

Large Format 3D Printers: These are designed for creating large objects, such as furniture or architectural models.

What materials can be used in 3D printing?

The range of materials available for 3D printing is vast and continually expanding:

-

Plastics: ABS, PLA, PETG, and nylon are common thermoplastics used in FDM printing.

-

Resins: Photopolymer resins are used in SLA printing for high-detail models.

-

Metals: Stainless steel, aluminum, titanium, and precious metals can be 3D printed.

-

Ceramics: Specialized printers can create objects from ceramic powders.

-

Composites: Materials like carbon fiber-reinforced plastics offer high strength-to-weight ratios.

-

Biomaterials: Some printers can work with living cells for tissue engineering applications.

What industries benefit from 3D printing technology?

3D printing has found applications across numerous industries:

-

Manufacturing: Rapid prototyping, custom tooling, and small-batch production.

-

Healthcare: Custom prosthetics, dental implants, and anatomical models for surgical planning.

-

Aerospace: Lightweight parts with complex geometries for aircraft and spacecraft.

-

Automotive: Prototyping, custom parts, and tooling for vehicle production.

-

Architecture: Creating detailed scale models of buildings and structures.

-

Education: Teaching design and engineering concepts through hands-on experiences.

-

Fashion: Producing unique jewelry designs and experimenting with textiles.

-

Food Industry: Creating intricate chocolate designs and exploring novel food presentations.

What are the advantages and limitations of 3D printing?

Advantages of 3D printing include:

-

Customization: Ability to create complex, one-off designs easily.

-

Rapid Prototyping: Quick iteration of designs for product development.

-

Reduced Waste: Additive process uses only necessary materials.

-

Decentralized Manufacturing: On-demand production closer to the point of use.

-

Complex Geometries: Ability to create shapes impossible with traditional manufacturing.

Limitations include:

-

Speed: Large or multiple objects can be slow to produce.

-

Material Limitations: Not all materials are suitable for 3D printing.

-

Surface Finish: Some methods may require post-processing for smooth surfaces.

-

Size Constraints: Most printers have limited build volumes.

-

Cost: Industrial-grade printers and materials can be expensive.

How much do 3D printers cost, and what should you consider when buying one?

The cost of 3D printers varies widely depending on the type, size, and capabilities:

| Printer Type | Target User | Price Range (USD) | Key Features |

|---|---|---|---|

| Entry-level FDM | Hobbyists | $200 - $500 | Basic features, small build volume |

| Mid-range FDM | Enthusiasts | $500 - $2,000 | Larger build volume, better precision |

| Professional FDM | Small businesses | $2,000 - $6,000 | High reliability, advanced materials |

| Desktop SLA | Professionals | $3,000 - $10,000 | High detail, smooth surfaces |

| Industrial SLS | Large enterprises | $100,000+ | Large build volume, production-grade parts |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

When considering a 3D printer purchase, factors to evaluate include:

-

Intended use (hobby, professional, or industrial)

-

Build volume required

-

Materials you plan to use

-

Print quality and speed needs

-

Budget for both printer and ongoing material costs

-

Software compatibility and ease of use

-

Manufacturer support and community resources

3D printing technology continues to evolve, offering new possibilities for creation and innovation across various fields. As the technology becomes more accessible and affordable, it’s likely to play an increasingly important role in both personal and industrial applications, reshaping how we design, manufacture, and problem-solve in the years to come.