Packing processes: Warehouse and Production Support Roles

Packing processes form essential components of manufacturing and distribution operations, involving systematic methodologies for product preparation, quality control, and inventory management. These processes encompass various technical procedures from initial product handling through final shipment preparation. Understanding packing methodologies provides insight into supply chain efficiency, operational standards, and the technical frameworks that support modern commerce and manufacturing systems.

Packing processes represent fundamental operational procedures within manufacturing and distribution systems, encompassing systematic approaches to product handling, quality assurance, and inventory management. These methodologies have developed into sophisticated frameworks that support modern supply chain operations across diverse industries.

Warehouse packing tasks

Warehouse packing tasks involve systematic procedures for organizing, verifying, and preparing products for distribution. These processes begin with inventory location systems that track product placement within storage facilities using numerical coding or barcode identification methods. Product verification procedures ensure accuracy through cross-referencing systems that match items against order specifications. Packaging material selection follows standardized protocols based on product characteristics, shipping distances, and protection requirements. Quality control measures include visual inspections, damage assessments, and compliance checks against established standards. Documentation procedures involve generating shipping labels, updating inventory databases, and maintaining traceability records throughout the packing process.

Production support processes

Production support processes encompass operational procedures that maintain manufacturing workflow efficiency and product quality standards. Material preparation involves organizing components according to production schedules, ensuring proper staging areas, and maintaining inventory accuracy through systematic tracking methods. Quality assurance procedures include testing protocols, specification verification, and defect identification systems. Equipment operation involves understanding machinery functions, safety protocols, and maintenance requirements for packaging equipment. Process documentation includes recording production metrics, maintaining compliance records, and generating operational reports that support continuous improvement initiatives.

Structured logistics work

Structured logistics work involves coordinating operational elements to ensure efficient product movement through supply chain networks. Inventory management systems track product quantities, locations, and movement patterns using computerized databases and scanning technologies. Transportation coordination includes scheduling procedures, carrier selection criteria, and delivery timeline management. Documentation management encompasses shipping records, regulatory compliance paperwork, and customs documentation for international shipments. Problem resolution procedures address operational disruptions through systematic troubleshooting approaches and corrective action protocols.

| Process Category | Technical Components | Industry Standards |

|---|---|---|

| Warehouse Operations | Inventory systems, packaging protocols | ISO 9001, warehouse safety standards |

| Production Support | Quality control, equipment operation | Manufacturing standards, safety regulations |

| Logistics Coordination | Tracking systems, documentation | Transportation regulations, customs requirements |

| Specialized Packaging | Environmental controls, compliance testing | Industry-specific regulations, quality standards |

Technical specifications and standards

Packing processes operate under various technical specifications and regulatory standards that ensure operational consistency and safety compliance. Safety protocols include proper handling techniques, equipment operation procedures, and hazardous material management guidelines established by occupational safety organizations. Technology integration involves warehouse management systems, automated sorting equipment, and data collection devices that support operational efficiency. Quality standards encompass packaging specifications, product protection requirements, and regulatory compliance measures specific to different industries. Environmental controls include temperature management, humidity regulation, and contamination prevention protocols.

Process optimization methodologies

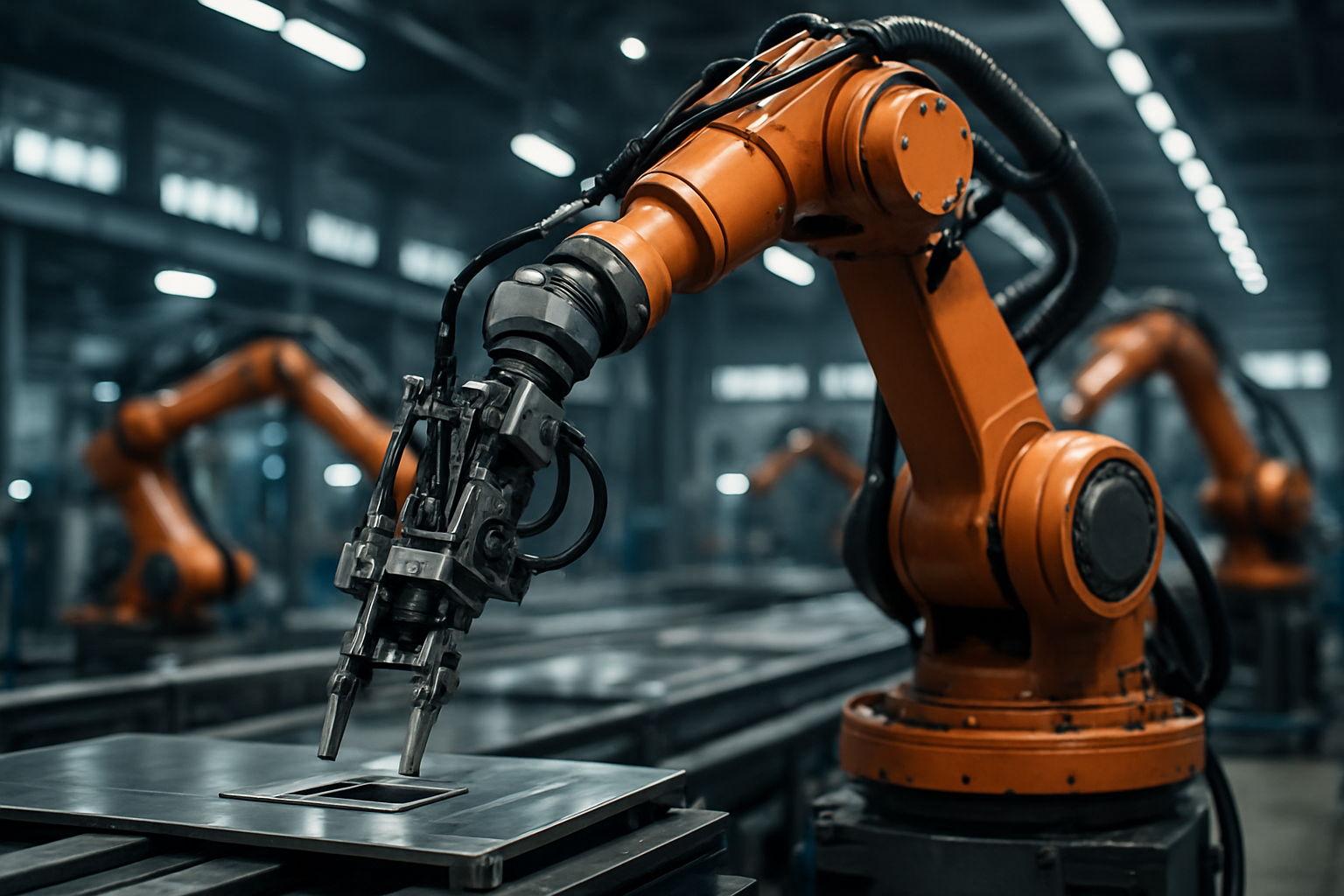

Modern packing operations emphasize systematic improvement through process optimization and technology integration. Automation technologies include conveyor systems, robotic handling equipment, and computerized inventory management solutions. Data analytics support operational decision-making through performance monitoring, trend analysis, and predictive maintenance scheduling. Lean manufacturing principles guide waste reduction, workflow optimization, and quality enhancement initiatives. Training protocols ensure operational consistency, safety compliance, and technology proficiency across different process areas.

Packing processes continue evolving through technological advancement, regulatory updates, and industry best practice development. These operational frameworks demonstrate the complexity and technical expertise required to maintain efficient supply chain operations across various industrial sectors.