Working for a Construction Company: Roles, Projects, and Operational Structure

Construction companies operate through carefully organized teams and processes that bring building projects to life. From initial planning to final completion, these organizations rely on diverse roles, coordinated efforts, and structured workflows. Understanding how construction firms function provides insight into one of the most essential industries shaping our built environment. This article explores the operational framework, team dynamics, and project execution methods that define modern construction work.

Construction companies function as complex organizations where multiple specialized teams work together to transform architectural plans into physical structures. The industry encompasses residential, commercial, industrial, and infrastructure projects, each requiring distinct approaches and expertise. Workers in this field engage with various project types throughout their careers, developing skills across different construction methodologies and building systems.

The organizational structure of construction firms typically includes office-based professionals and field personnel. Management teams handle project bidding, client relations, budgeting, and regulatory compliance, while field crews execute the physical work. This division ensures that administrative responsibilities and hands-on construction progress simultaneously, maintaining project momentum and meeting contractual obligations.

How Does Collaboration Function Across Construction Teams?

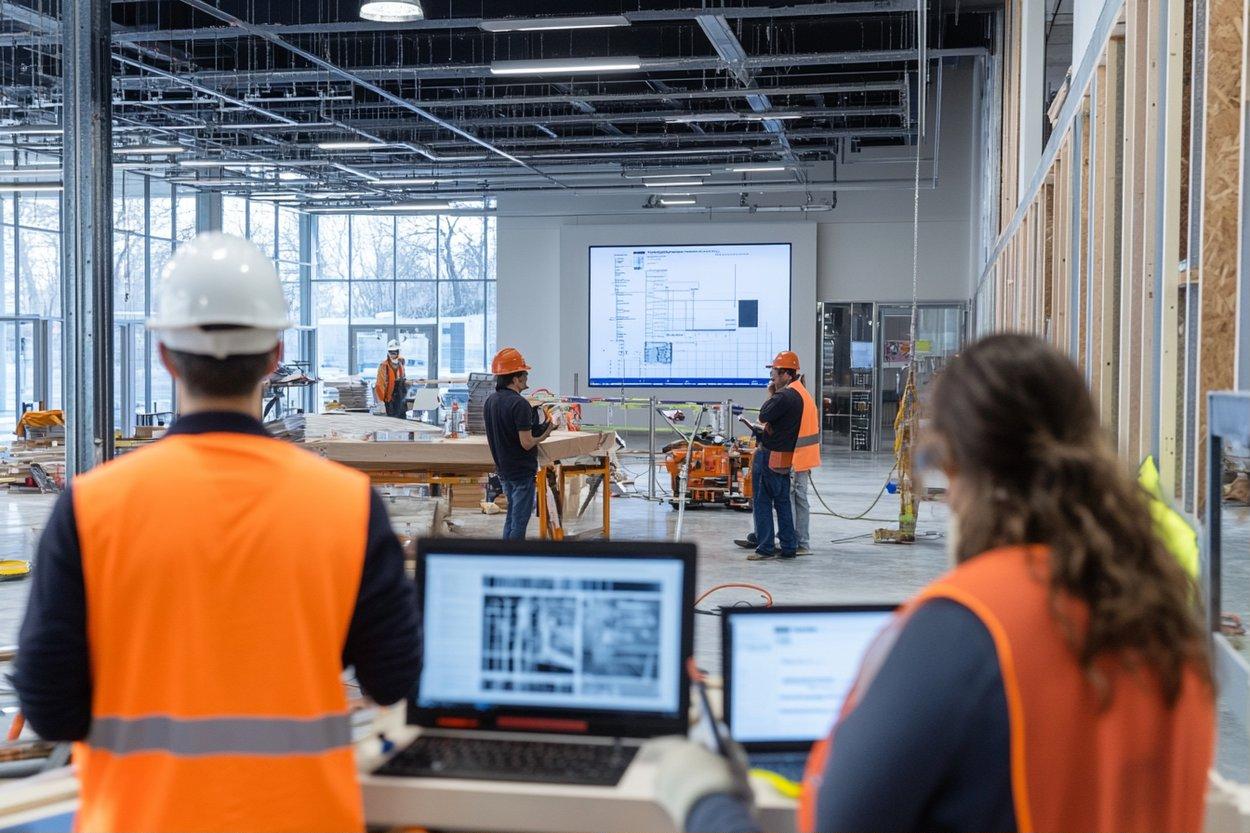

Effective collaboration forms the foundation of successful construction projects. Site superintendents coordinate daily activities among subcontractors, ensuring that electrical, plumbing, framing, and finishing teams work in proper sequence. Regular coordination meetings address scheduling conflicts, material deliveries, and safety protocols. Communication channels between field supervisors and project managers keep everyone informed about progress, challenges, and necessary adjustments.

Trade-specific crews often work for specialized subcontracting firms rather than the general contractor directly. This arrangement allows companies to maintain flexibility in workforce allocation while accessing expert tradespeople for specific project requirements. Coordination between these independent teams requires clear documentation, shared schedules, and mutual accountability to prevent delays and quality issues.

Digital tools have transformed team collaboration in recent years. Project management software, mobile applications, and cloud-based document sharing enable real-time updates from job sites. Workers can access blueprints, submit progress reports, and flag issues instantly, reducing miscommunication and improving response times to emerging challenges.

What Determines Construction Work Aligned with Project Phases?

Construction projects progress through distinct phases, each requiring specific skills and resources. The pre-construction phase involves site preparation, permitting, and mobilization. Foundation work follows, establishing the structural base. Framing and structural systems come next, creating the building skeleton. Enclosure work protects the interior, allowing mechanical, electrical, and plumbing installations to proceed regardless of weather.

Interior finishing represents the final major phase, including drywall, flooring, cabinetry, and paint. Throughout these stages, inspection points ensure compliance with building codes and design specifications. Workers move between projects as their specialized skills become necessary, with employment patterns reflecting these cyclical demands.

Seasonal factors influence project scheduling and workforce allocation. Certain activities like concrete pouring and exterior work face weather constraints, while interior tasks can proceed year-round. Companies adjust staffing levels and project timelines accordingly, balancing workload distribution with environmental conditions and client deadlines.

How Is Workforce Organization Structured in Building Projects?

Construction workforce organization follows hierarchical structures that define responsibilities and reporting relationships. General contractors oversee entire projects, managing budgets, schedules, and subcontractor coordination. Project managers handle day-to-day operations, while site superintendents supervise field activities directly.

Craft workers form the operational core, performing specialized tasks within their trades. Apprentices work alongside experienced journeymen, learning techniques through hands-on experience. This mentorship model perpetuates skill development while maintaining productivity standards. Safety officers monitor compliance with regulations, conducting training and enforcing protective measures.

Large projects may employ dedicated quality control inspectors, schedulers, and materials coordinators. These support roles ensure that construction proceeds according to specifications, timelines remain realistic, and necessary supplies arrive when needed. Administrative staff handle payroll, equipment management, and documentation requirements that support field operations.

What Enables Coordinated Schedules and Task Planning?

Effective scheduling requires understanding task dependencies and resource availability. Critical path method planning identifies which activities must complete before others can begin, preventing bottlenecks. Schedulers account for material lead times, equipment availability, labor capacity, and inspection requirements when developing timelines.

Weekly work plans translate long-term schedules into actionable daily tasks. Foremen assign crews to specific activities, considering skill levels, safety requirements, and productivity expectations. Flexibility remains essential, as weather, material delays, and unforeseen conditions frequently necessitate adjustments.

Look-ahead scheduling anticipates upcoming needs, allowing procurement teams to order materials and equipment rental companies to reserve necessary machinery. This proactive approach minimizes downtime and keeps crews productive. Regular schedule updates reflect actual progress, helping stakeholders understand project status and make informed decisions about resource allocation.

Technology integration has improved scheduling accuracy significantly. Building Information Modeling links three-dimensional designs with timeline data, visualizing construction sequences and identifying potential conflicts before they occur. Mobile scheduling applications allow field personnel to update progress instantly, providing real-time visibility into project status.

What Career Paths Exist Within Construction Companies?

Construction offers diverse career trajectories for individuals with varying educational backgrounds and interests. Entry-level positions provide opportunities to learn trades through apprenticeships or helper roles. With experience, workers advance to journeyman status, gaining independence and higher compensation.

Management tracks appeal to those interested in project coordination and business operations. Assistant project managers support senior leaders before assuming full project responsibility. Some professionals specialize in estimating, analyzing project costs and preparing competitive bids. Others focus on safety management, ensuring regulatory compliance and protecting worker wellbeing.

Technical specialists in areas like surveying, quality control, and Building Information Modeling provide essential support services. These roles often require specific certifications or technical education. Company ownership or executive leadership represents the ultimate advancement for entrepreneurial individuals who develop comprehensive industry knowledge and business acumen.

How Do Construction Companies Maintain Operational Standards?

Quality control systems ensure that completed work meets design specifications and regulatory requirements. Inspection checklists guide systematic reviews at critical project milestones. Documentation photographs and test results provide evidence of compliance, protecting companies from future liability claims.

Safety programs form another crucial operational component. Regular toolbox talks address specific hazards, while comprehensive training covers equipment operation, fall protection, and emergency procedures. Incident investigation processes identify root causes of accidents, enabling corrective actions that prevent recurrence.

Continuous improvement initiatives help construction companies refine their processes. Post-project reviews assess what worked well and what needs adjustment. Lessons learned inform future planning, gradually enhancing efficiency, quality, and safety performance. Companies that systematically evaluate and improve their operations gain competitive advantages through superior execution and client satisfaction.

Construction work demands physical stamina, technical knowledge, problem-solving abilities, and teamwork skills. The industry offers stable career opportunities for dedicated individuals willing to develop expertise and adapt to evolving technologies. Understanding organizational structures, project phases, and collaborative processes provides valuable context for anyone considering or currently pursuing construction careers.